How To Add Freon To Ac Unit At Home

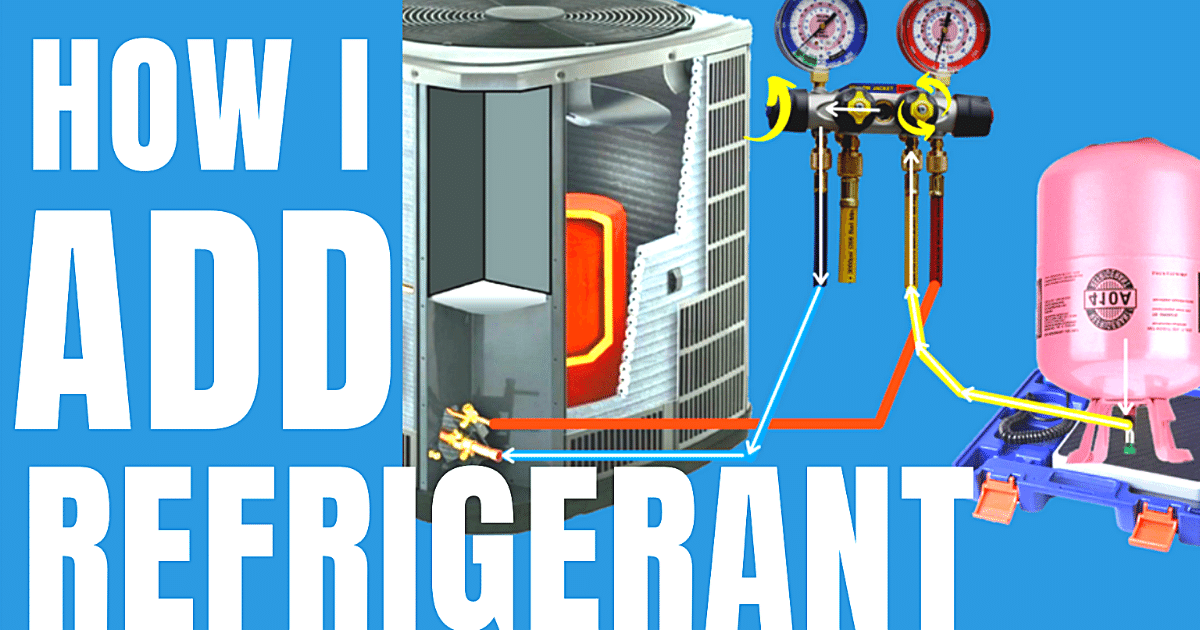

Hey HVAC techs! I'm Greg Fob, and today we're going to talk about adding more refrigerant to an air conditioner. I wanted to expand on our recent Air conditioning troubleshooting series past going into each role of its sequence of operations. This week, it'due south the refrigerant.

Now, I'm not going to get into the legalities and moral issues here of refilling refrigerant on a organisation that is leaking, but you should know a few things:

- Refrigerant is expensive for the client – If you have to keep refilling their refrigerant, which nosotros exercise non know how oft that will be, it tin add together upwardly chop-chop.

- They know their air conditioner better than us. If we've never been to their home to refill their refrigerant before, in that location's no reference for knowing how Large their refrigerant leak is or WHERE the leak is.

- The customer could lose all of their refrigerant tomorrow if they have a significant leak… or if information technology is a small leak, the refrigerant could concluding them all yr or longer.

Let'southward go over some basics to charging an air conditioner on your average 90-caste 24-hour interval in the center of summer. Upon arrival at the business firm, your customer tells you the air conditioner worked simply fine last year, simply this year the arrangement seems to run non-cease, especially every bit the summer days get hotter and hotter. You lot enquire the customer, "Accept any other technicians been out to make repairs on your arrangement since last year?" It'due south very probable the customer volition say no.

In that location'due south a lot of things that can impact the refrigerant charge. Just remember, for the sake of time, we're keeping this dialogue short, so we can become to the point of charging the system upward.

I like what Bryan Orr mentioned in an article I read. He said,

"Nosotros demand to set up equipment so that it won't freeze during normal operating weather condition. At the very least, the typical residential A/C arrangement should be set up and so that the render air temp can go all the way down to 68° and still exist just above freezing at the evaporator roll.

Permit's say it's 78° in a business firm on an R410a organisation, and your suction pressure level is 108 PSI. That ways your suction saturation (curl temperature) is 35°… and then the coil won't freeze.

However, the coil temperature will drop approximately one° for every degree the return temperature drops.

Recollect, at 78° inside, the evap coil was at 35°, So if the customer sets it down to 74°, the saturation would get down to 31°, and the will start to freeze.

Knowing this, let's grab your temperature probe and bank check the return air and the supply air. Here you notice the departure between the two is nigh 8 degrees. Equally a tech, you know the divide should be effectually 18 to 22 degrees.

Adjacent, you head outside and feel the suction line to run into if information technology'south cold. Now, in that location is some validity to the old term, "beer tin common cold" just information technology should not be the measure you go past to check the refrigerant accuse. It can, however, requite you a clue as to the condition of the system. In this case, the suction line at the Ac is barely cold. At present, I'yard not e'er a huge proponent of hooking my gauges up to a system every fourth dimension I go out to diagnose a organization, simply in this example, nosotros can tell something's non correct with the cooling system, so in this instance, I desire to see what is going on inside of it.

Claw your hoses up to the liquid and suction lines. Be conscientious of blowback so you don't freeze your hands. Follow all safety precautions.

Now, what do you see on your suction side? I like my techs to talk to me nigh the evaporator coil'southward TEMPERATURE and the TEMPERATURE of the condenser roll. When I'm on the phone trying to help a tech out in the field, it's difficult for me to retrieve all the pressure-temperature ratios between the different refrigerants we use.

And then if someone tells me the evaporator scroll is 40 degrees, I can immediately tell the coil is not freezing. If someone tells me the temperature of the condenser curl is 140 degrees, I tin immediately translate that to an outdoor coil that is nether some seriously high pressure.

On the refrigerant guess, the outer circle and those numbers are the pressures. The inner rings of numbers reverberate the temperature. This is how I desire my techs to communicate pressures to each other. It's more than efficient this way. Most gauges these days have a greenish ring for R22 and a pinkish ring for R410. The pink ring's numbers are what nosotros are using for evap and condenser coil temperatures on a 410 system.

Here we see that the evaporator roll is at about xx° F. For proper refrigerant levels, the image I desire you to projection in your heed is this. Our cease-goal here is to have liquid refrigerant reach all the way to the TXV at the evaporator whorl to meter the refrigerant appropriately. Right at present, there's non enough liquid in the system to do that. This means vapor is making its way to the metering device, and we're not giving the coil enough refrigerant to interact with the speed of the blower air moving across it.

We need the perfect balance of airflow and refrigerant pressures to create that 18 to 22-degree temperature split we are looking for.

Let's suppose this arrangement holds 10lbs or R-410a. In my mind, I'm thinking the system is about halfway charged. It's an approximation, simply we have to let the client know about how many pounds we want to add together, so they give you the okay to move frontwards. Of course, you don't know for sure, merely they should be aware it could be around 5 lbs, and that volition toll (whatsoever, $100 a pound). We need to let them know it could be a couple of pounds more or a couple of pounds less, but either style, we need permission to motion forrard.

Using a scale is the but mode we tin know for sure how many pounds of refrigerant we are adding. And it's cool to allow the customer know you'll exist using this also. It's reassuring to them. This is bang-up for preventing you from overcharging the system likewise.

My service hoses are already hooked upward. I'm going to commencement by putting my charging hose on the tank of refrigerant. Next, I open the refrigerant tank valve and place information technology upside downwards on the scale. With the gauges airtight on the manifold, I cleft open the connectedness where the charging hose meets the manifold. Non too much, though. We just want the refrigerant to prime itself up to that point so we get rid of excess moisture and air in the hoses.

Reset the calibration back to zero, so we know how much nosotros are adding as the refrigerant enters the system.

I recommend you put an amp clamp on one of the wires leading to the compressor. If you've seen my video on diagnosing a bad compressor, you know that the compressor'southward amp draw correlates with the refrigerant pressures inside the system. The healthiest compressors will run at around 60 percent of their RLA. When y'all're charging up the organisation, y'all'll see the amp draws fluctuate as the refrigerant goes in and settles downwardly. Use your knowledge about the compressor amp draws to monitor your charging process.

Okay! We're ready to charge! With the charging hose valve open, nosotros'll start opening the suction side valve. A quarter to half of a plow is enough. There is no estimate amount of fourth dimension information technology'll accept to insert 1 lb. of refrigerant. Each situation is different. To know for sure, use your scale.

In this situation where we recall the system is virtually 4 or 5 lbs low, permit nearly 2 lbs flow into the organization and wait for 5 to 10 minutes for the system to equalize. Question. How long does it take for the refrigerant to cycle through a typical residential split up organisation? I'd say about iii or four minutes. If you take a unlike reply, permit me know in the comments.

And so nosotros see now the low side has come up up to well-nigh 27 degrees or 92 psi. Our evaporator curlicue is still freezing. Permit's add together two more pounds and wait. I know there'south a lot of pressure on techs to go their calls done speedily so they tin get to the next i, but it's essential to allow the arrangement stabilize before adding more than refrigerant. If you add too much, too shortly, y'all could run across the pressures skyrocket insanely fast. And now you have to recover some refrigerant into a separate tank which takes fifty-fifty more time!

Now we are getting close to 32 degrees or about 100 psi on the suction side. From hither, we want to commencement dialing our subcool to whatever information technology is the manufacturer recommends. This system says x degrees subcooling on a 95-degree day. Let's get a temperature probe on the liquid line and commencement getting our reading from it. We're going to be subtracting the high side's temperature and the liquid line's temperature to come upwardly with our subcooling.

Add together refrigerant a trivial at a time until the difference between those two numbers is 10 degrees. There's nothing tricky about this. Just don't add too much as well fast. Add refrigerant and expect for the numbers to stabilize.

You lot're going to exist looking for the low side pressure level to be around 40 to 42 degrees or 125 psi. The high side pressure/temperature will likely settle around fifteen degrees to a higher place the outdoor temperature. So on a 90-degree day, you may end up with a loftier side temperature effectually 105 degrees. If y'all can get your numbers around this area, you're close! Simply let's really go it dialed in. Go that subcool to 10, plus or minus 2 degrees.

I will tell you; it takes longer to motion the needle on your gauges when in that location's less refrigerant in the organization. Every bit the arrangement starts getting shut to the proper subcool, you'll desire to finesse the time y'all go on the manifold open up, allowing refrigerant into the arrangement. Overcharging can happen chop-chop, especially on a hot twenty-four hour period.

Getting close to your 10 degrees subcool? Cool!

Once you get information technology to this point, bank check your temperature dissever inside. Is it around 18 to 22 degrees? Great! You'll notice the liquid line is a little bit warmer than the outdoor temperature. As well, the suction line will be damn nigh "beer can cold!"

Test the organisation while it'due south running. Get your amp draws on the condenser fan motor and compressor. Cycle the organisation on and off at the thermostat to brand certain the organization is operating correctly. If it is, you're practiced to go.

Well, I hope this has helped yous when it comes to the charging procedure. I make my videos for my technicians to reference when they are in a bind out in the field. Only if this can assist anyone else, that's great.

Thanks and so much for reading, and nosotros'll see you on the next web log.

https://youtu.exist/plTCLJF_zQk

How To Add Freon To Ac Unit At Home,

Source: https://www.foxfamilyhvac.com/how-i-add-refrigerant-to-a-central-air-conditioner/

Posted by: clearyhishowas.blogspot.com

0 Response to "How To Add Freon To Ac Unit At Home"

Post a Comment